Bespoke

Why Cairn?

Bespoke Jewellery at Cairn Diamonds is like no other, we have years of experience in it. We love every request, every measurement and every stone no matter how difficult to source. When you come to us with nothing else but a dream, it’s our complete passion to make it become truly real.There are many occasions when you might have one image, one memory of a item with no other details to go from, we are here to help people like you go through shapes, profiles, calculate carat weights (Yes even all of those baguette measurements!), create designs until we’ve uncovered the most beautiful aspects of your imagination.

Explore the process below…..

Step One: CAD

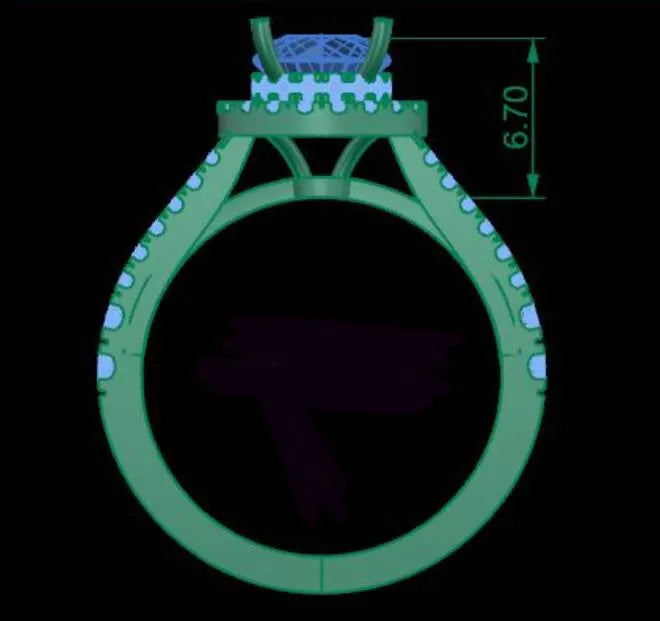

After our initial consultation where we have explored your ideas, inspirations and impact you would like the piece to have, we then move forward to the CAD Phase. The ideas presented are relayed to our CAD design team who begin to form the structural foundations of the ring.

This include: Diamond Measurements, Band Width and Profile (Rounded, Curved, Flat or Tubular), Finger size, Design, Height, Total Carat weights, Claw style. Once perfected, you will be sent the design from different perspectives.

This design really is yours, from this stage we are able to tweak and perfect the shapes, distances between stones, band width or even apply tapers (Varying widths within one band).

Step Two: Wax

You could request variations or more likely- love the very first edition!

However there are sometimes where you might want to visualise it more. We can achieve this by creating a 3D Printed Wax for you. These waxes are printed from your exact CAD design meaning they are beautifully precise to scale giving you the exact proportions you can hold in your hand (But carefully!).

Waxes are excellent- but not if we don’t have much time! The printing stage for viewing can take a few days to create and so on urgent orders (Making in under 2 weeks) We will likely have to move past this stage, but rest assured the CAD designs are so accurate the rings look even more spectacular once they are done!

Step Three: Casting

When you have approved the design, it is sent for casting. This is a fascinating stage where the molten metal flows into all areas and takes the shape of the printed design.

This stage is very important as not only it brings the design into a real precious metal form but also for the structural importance on a microscopic and atomic level. If a ring which has been rushed casted or used with a cheaper, lighter alloy to make the metal go further (Often an identifying mark that a ring has been manufactured cheaply over seas.) Will often contain porosity. Porosity is when small bubble and disorientated internal structures have formed within the metal, making it weaker.

At Cairn Diamonds are very proud of the metallurgic research we have done in our alloys providing the hardest, toughest and most thorough modern casting techniques. After casting we use X-rays to scan the internal structure to ensure no ring leaves with porosity. We build our rings to last a lifetime.

Step Four: Crafting

After the casting has been quality checked, we bring it to our spectacular workshop in Hatton Garden, London. This fabulous place has been at the forefront of Jewellery Manufacturing, Precious Stones and Metals dealing for centuries.

Within the this brilliant pandemonium is where we give the rings their unique sparkling spirit. We begin through polishing the casting, working patiently through every aspect of the ring from the claws to the band profile bringing up the true shine of the metal beneath.

Once the initial polish has been completed we begin the stone setting, an intricate part of tailoring the metal around each Gem. Each stone has been precisely calculated to fit perfectly within its rightful place inside the ring. When it is placed inside the claws are shaped over the stone and tightened, this continues until all stones are set and the claws shaped.

We then have the final polish where the jewellery is refined to be the glistening beacon of happiness you’ll always smile at.

Step Five: Hallmarking

Upon passing Quality Control in the workshop ensuring the Jewellery and stones are perfectly secure. That there are no scratches or marks are upon the metal, the ring will move through to the final stage. Hallmarking.

This ancient tradition has been performed since Circa 1327 in the United Kingdom. Throughout this time it has guaranteed the quality of precious metals being both imported, exported and sold within the UK. Providing assurance that what is being advertised is what you will physically receive.

We provide all of our Jewellery (Where sizing allows) to be Hallmarked and take great pride in keeping this historic tradition alive whilst also providing further assurance to our valued clients.

We are very proud to be registered members of the UK Assay Offices and follow the requirements of the Hallmarking Act 1973.

(Please note: Hallmarking may take several days to complete and may not be possible within your delivery dates on some urgent orders.- However you will be able to bring back your Jewellery after you required date and we will happily have this added for you.)